Remote Monitoring of Pumping Station

Build a monitoring center to achieve unattended

Equipment remote monitoring

Data is online in real time

Efficient fault alarm

Data report analysis

Equipment remote maintenance

Process flow visualization

With the development of cities, pumping stations, as water supply hubs, play a very important role in residential and industrial water use. There are more and more pumping stations, and their distribution is scattered. Issues that water companies must consider. For the traditional monitoring of pumping stations, the staff is used to check regularly, and sometimes the personnel are negligent, resulting in abnormal operation of the pumping station. At the same time, this method is very troublesome for the monitoring of multiple pumping stations; the data between different pumping stations cannot be effectively integrated. Together, data warning and equipment maintenance cannot be carried out through big data. Therefore, in this context, Wutong Bolian adopts the industrial intelligent gateway to realize the collection and processing with the pump room PLC to remotely monitor the pumping station, and at the same time realizes the data of the pumping station through the Wutong Bolian cloud platform or the customer's self-developed cloud platform. Forecasting, equipment remote maintenance and data sharing.

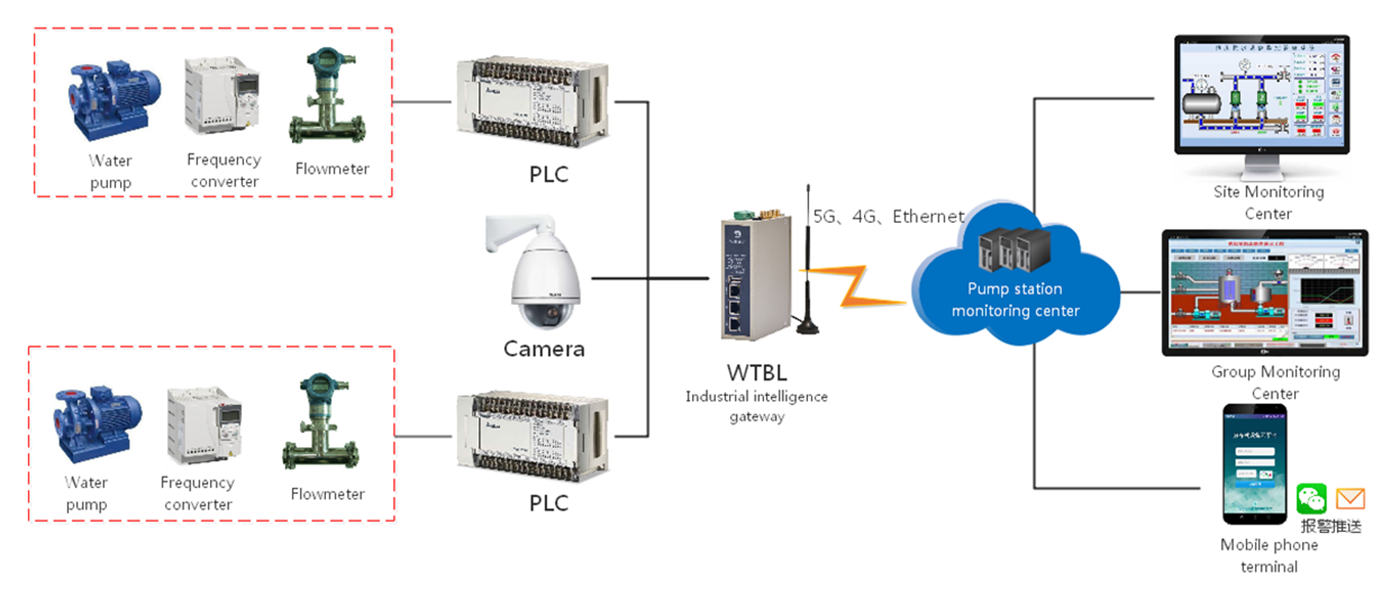

The WideIOT industrial intelligent gateway is connected to the pump room PLC controller, collects the operating status of the pump station in multiple directions, accesses the Internet through 5G/4G/WIFI, etc., and transmits the data to the pump station monitoring center (Wotong Bolian equipment data cloud platform or self-developed cloud platform); managers can remotely monitor the status of the pump station at any time in the pump station monitoring center or terminal, and colleagues can remotely configure, diagnose and modify the pump station PLC program through the equipment express line, so that the pump station is unmanned. on duty.

Internet of Everything

Intelligent Collection

Edge Computing

Cloud Application

Equipment remote monitoring

Realize remote monitoring of pumps, frequency converters, flow meters, PLCs and other equipment in pumping stations

Data is online in real time

The data is transmitted to the monitoring center of the pump station, and the status of the station can be remotely monitored at any time.

Efficient fault alarm

Automatic alarm for equipment failure, and alarm information is automatically pushed to the manager's phone

Equipment remote maintenance

Remote configuration, diagnosis and modification of the PLC program of the pump station are realized through the equipment express line to ensure the healthy operation and service life of the equipment.

Process flow visualization

Configuration monitoring to realize visual monitoring and management of process flow

Data report analysis

Integrate and analyze data from multiple dimensions, provide big data support for pumping stations, and facilitate digital management and operation

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Wtunnel

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.

click to view detail>>

-

WCloud

WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.

click to view detail>>

-

WLink

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>> WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>>

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>> WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>>

WideIOT·The industrial equipment data platform is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>> WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

Go Top

Go Top